采用短捷有力的双缸射出系统,射出动作平稳,及定模板无变形,优化设计螺杆组件,达到好的塑化能力。螺杆头和止逆环采用日本热作工具钢之高韧性材料。经热处理,具有抗高温、避热熔蚀之特性,在高温作业下仍高硬度,螺杆、料管采用合金钢加真空离子氮化处理,具有仍维持硬度、耐腐蚀、避磨耗之特性。

PID温度控制,配合精度电子尺和控制器,注射、保压、熔胶、背压等动作的速度压力,保障成型制品品质和生产的连续性,自动清料,避流涎、避冷起动等功能,工作的意义、简便、良好。精度机器采用双射移油缸,以及线型导轨引导、低阻力。

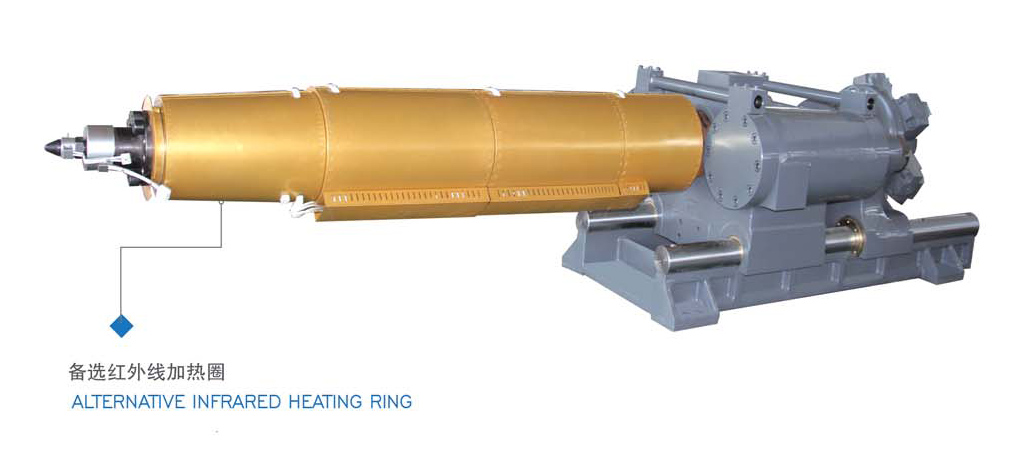

Short and forceful double-cylinder injection system is used to ensure the steady injection motions. The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticizing capacity and effect. The screw head and back stop ring made of Japanese high tenacity hot working tool steel by special heat treatment features high temperature resistance, wear endurance and hot burnout resistance, maintaining extremely high hardness during high temperature operation. The screw and barrel made of high-grade alloy steel by vacuum ion nitriding treatment feature high hardness, corrosion resistance and wear endu-rance.

PID temperature control in combination of high precision electronic ruler and control regulate the speed and pressure of injection, pressure keeping, smelting, back pressure and other motions to ensure the quality of formed products and continuation of production. Auto material preparation,drooling proof, and anti cold start lapse functions ensure the high efficient, simple and safe operation. High-precision machines used two-shot move the fuel tank, as well as the linear guide rail, accurate,low-resistance.